01 Dec Power-Packer’s Hydraulic Legs Rock!

In an average year, more than 900 million tons of sand and gravel, and well over a billion tons of crushed stone, are produced in the U.S. Nationally, construction aggregates are a multi-billion-dollar industry and the most mined materials in the world. Every town and city in our country — and all of the roads connecting them — were built, and continue to be maintained, with aggregates.

The crush is on

Powerful rock crushing equipment turns stones and minerals into useable aggregates. After being extracted from their source, rocks and minerals undergo a complex process that typically includes four phases:

- Primary crushing: Jaw, cone, roll, gyratory, impact crushers and mills are used to reduce materials to average sized pieces

- Secondary crushing: Pieces are further crushed to the desired size

- Sorting: Crushed rock is fed through screens and sorted into tradable fractions

- Washing: Certain types of raw material, such as sand and gravel, must be washed and purified

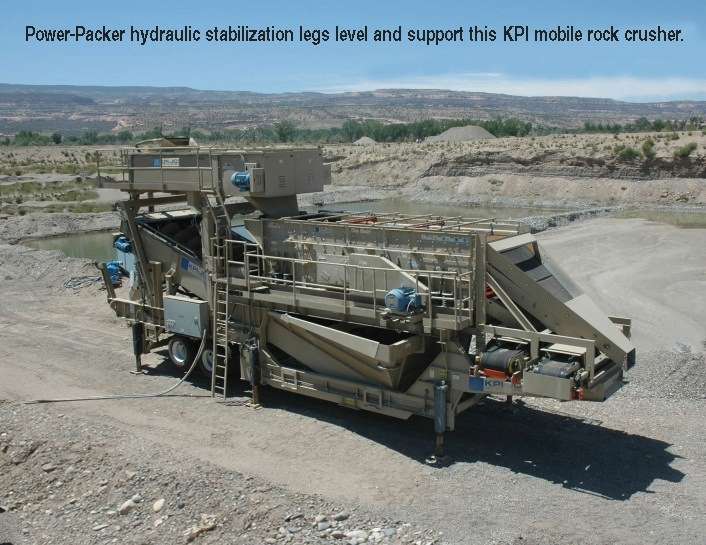

While some rock crushers are stationery, many industries need portable equipment that can be moved on wheels from job site to job site. Tasked with such a weighty task, mobile rock crushes require a little extra help from stabilization legs. Heavy-duty stabilization legs level and support mobile rock crushers to ensure continued operation and safety for all.

Power-Packer’s hydraulic stabilization legs for rock crushers

Power-Packer offers 4”, 5” and 6” bore hydraulic stabilization legs for leveling and holding mobile crushing plants in the field. Designed to withstand the harshest environments, our legs arrive completely assembled and tested with a bolt-on, outer tube mount conveniently integrated into the design. Plus, our legs and mounting brackets can also be customized to meet your exact specifications. Leading OEMs around the globe trust the smart design and durability of Power-Packer legs to ensure fast set up and take down and ongoing reliable operation.

What is a stiff leg?

Some OEMs rely on hydraulic legs to lift and position mobile crushing plants, while a stationery structure or “crib” is moved into place to hold it securely. In other instances, “stiff” or “run on” hydraulic legs are used to hold the crusher in place during operation. These are called “stiff” legs because they have a secondary mechanical locking feature to prevent any leg movement once in positon. Power-Packer offers a variety of regular and “stiff” legs to meet your exact application needs.

Designed for optimal efficiency and safety

Power-Packer hydraulic stabilization legs have smart and flexible design features to prevent downtime, improve productivity, and maximize worker and equipment safety. Features and benefits include:

- Integrated load holding/relieving valves eliminate the potential for catastrophic failure

- Adjacent hoses ensure quick and easy plug in, and fastest set-up

- Fully contained lower leg design prevents environmental contaminants from reaching hydraulic cylinder

- Dual guide rings inside an outer mount tube offer side load advantage and save on wear

- Optional mechanical locking for maximum safety and flexibility

- Hydraulic lift capacities from 37,000 lbs. up to 70,000 lbs.

- Mechanical load holding up to 170,000 lbs.

- 10% side-load capacity

- Bore size from 4” to 6”

- Stroke lengths from 12” to 36”

- SAE work ports for reduced leak potential

- Lock nut threads designed to withstand external contaminants

- Customizable mounting brackets to meet your exact specifications

- Variety of footpads available in fixed, articulated and removable styles

Choosing the Right Stabilization Legs for Your Mobile Crusher

Ready to customize stabilization legs for your mobile rock crushing plant? Here are considerations to help you combine the right components for your need. Of course, Power-Packer engineers and sales professionals are readily available to answer your questions and provide guidance.

- How heavy is the plant?

- What leg lift capacity is needed? Be sure to consider empty and full load weights.

- How many legs will you need? The number of legs is determined by the weight of the crusher and the load capacity of the leg. Crushers typically have 4 to 6 legs. Ex. Load rating for a 6” leg is 70,000 lbs., while a 4” leg is 37,000 lbs.

- What is the load bearing capability of the ground? Legs must sit on stable ground. If the soil is softer, you may need a footpad to ensure proper ground contact.

Download our full-line brochure to see available products and specifications.